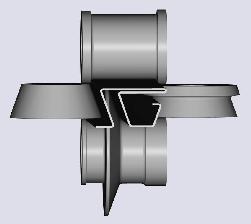

Die (manufacturing)

|

Read other articles:

В Википедии есть статьи о других людях с такой фамилией, см. Блюхер; Блюхер, Василий. Василий Константинович Блюхер Военный министр Дальневосточной республики 27 июня 1921 — июль 1922 Глава правительства Николай Матвеев Предшественник Василий Иванович Буров Преемник Конст

British newspaper publisher News International redirects here. For the Pakistani newspaper, see The News International. For the US Socialist Workers Party magazine, see New International. For the British magazine, see New Internationalist. News Corp UK & Ireland LimitedSouth side of The News Building, LondonTrade nameNews UKTypeSubsidiaryIndustryMass mediaFoundedFebruary 1981; 42 years ago (1981-02)HeadquartersLondon, United KingdomKey peopleRupert MurdochJames Murdoch…

Artikel ini sudah memiliki referensi, tetapi tidak disertai kutipan yang cukup. Anda dapat membantu mengembangkan artikel ini dengan menambahkan lebih banyak kutipan pada teks artikel. (Pelajari cara dan kapan saatnya untuk menghapus pesan templat ini) Masabumi Hosono (細野 正文code: ja is deprecated , Hosono Masabumi, 15 Oktober 1870 – 14 Maret 1939[1]) merupakan satu-satunya orang Jepang yang menaiki RMS Titanic. Dia meninggal pada tahun 1939. Perjalanan Tulisan Masabumi Hosono m…

美術館が位置するブダ城 ハンガリー国立美術館(ハンガリー語: Magyar Nemzeti Galéria)とは、1957年に設立された、ハンガリーの国立美術館であり、首都ブダペストのブダ地区にあるブダ城内に位置している。その収蔵する分野は、ハンガリー美術全体に及び、19世紀から20世紀にかけてパリ等の西欧で活躍したハンガリー美術家の物も多く含まれている。 収蔵品 ピラトの

?Мізида зубчаста Біологічна класифікація Царство: Тварини (Animalia) Тип: Членистоногі (Arthropoda) Підтип: Ракоподібні (Crustacea) Клас: Вищі ракоподібні (Malacostraca) Ряд: Мізиди (Mysida) Родина: Мізидові (Mysidae) Рід: Hemimysis Вид: Мізида зубчаста Біноміальна назва Hemimysis serrataBacescu, 1938 Посилання EOL: 128021 ITIS: …

غلة المحاصيل في الزراعة، تشير «غلة المحاصيل» والتي يطلق عليها «الإنتاج الزراعي» إلي كلًا من مقياس المحصول لكل وحدة من مساحة الأراضي المزروعة أو جيل بذورمن نفس نوع النبات، على سبيل المثال إذا حُصِدَت ثلاث حبات لكل بذرة، فنتاج المحصول هو 1:3ويعتبر هذا الرقم من قبل المهندسين ال…

هذه المقالة يتيمة إذ تصل إليها مقالات أخرى قليلة جدًا. فضلًا، ساعد بإضافة وصلة إليها في مقالات متعلقة بها. (نوفمبر 2019) كيسي باتن معلومات شخصية الميلاد 7 مايو 1874 الوفاة 31 مايو 1935 (61 سنة) روتشستر مواطنة الولايات المتحدة الحياة العملية المهنة لاعب كرة قاعدة ال…

Gatchaman CrowdsPoster promosi yang menampilkan karakter utama (bawah kiri ke kanan) Joe, Sugane, Paiman, Hajime, J.J., OD, Utsutsu, (top) Rui dan Katze.ガッチャマン クラウズ(Gatchaman Kurauzu)GenreLaga, Fiksi ilmiah, Superhero Seri animeSutradaraKenji NakamuraSkenarioToshiya OnoMusikTaku IwasakiStudioTatsunoko ProductionPelisensiAUS HanabeeNA Sentai FilmworksUK Animatsu EntertainmentSaluranasli NTV SpacetoonSaluran bahasa InggrisSEA Animax AsiaTayang 12 Juli 2013 – 27 September 2013…

الشركة الوطنية للإذاعة والتلفزةSociété nationale de radiodiffusion et de télévisionJenisPerusahaan milik pemerintahIndustriMedia massaGenreLayanan penyiaran masyarakatPendiriPemerintah MarokoKantorpusatRabat, MarokoWilayah operasiMaroko, Eropa, Timur TengahTokohkunciFayçal Laâraïchi, Presiden (PDG)JasaTelevisi, radio, daringPemilikPemerintahan MarokoKaryawan2,300Situs webwww.snrt.ma Société nationale de radiodiffusion et de télévision (SNRT) adalah penyiara…

Virus hepatitis B Hepatitis B virus Komposisi genom virus ICTVdouble-stranded DNA reverse transcriptase virus (en) PenyakitHepatitis B dan Hepatitis E TaksonomiSuperdomainBiotaDomainVirusFamiliHepadnaviridaeGenusOrthohepadnavirusSpesiesHepatitis B virus lbs Untuk penyakit, lihat Hepatitis B. Virus hepatitis B (sering disingkat HBV) adalah virus DNA untai ganda,[1] spesies dari genus Orthohepadnavirus, dan anggota dari famili virus Hepadnaviridae.[2] Virus ini menyebabkan penyakit…

Football Club Internazionale Milano is an Italian association football club based in Milan, Lombardy. The club was formed on 9 March 1908 to allow the foreign players to play in Italy.[1] Inter played its first competitive match on 10 January 1910 against their cross-town rivals Milan, in which they lost 3–2.[2] The club won its first title in 1910 – the 1909–10 Italian Football Championship. In total, the club has won nineteen league titles along with nine Coppa Italia and…

يفتقر محتوى هذه المقالة إلى الاستشهاد بمصادر. فضلاً، ساهم في تطوير هذه المقالة من خلال إضافة مصادر موثوق بها. أي معلومات غير موثقة يمكن التشكيك بها وإزالتها. (مارس 2016) سد ردي دولة الجزائر موقع الجزائر تعديل مصدري - تعديل يقع سد بوقارة في بلدية بوقرة ولاية تيسمسيلت الجزا…

American politician For other people named James Graham, see James Graham (disambiguation). This article needs additional citations for verification. Please help improve this article by adding citations to reliable sources. Unsourced material may be challenged and removed.Find sources: James Graham North Carolina politician – news · newspapers · books · scholar · JSTOR (May 2021) (Learn how and when to remove this template message) James Graham. Jame…

لمعانٍ أخرى، طالع رود سميث (توضيح). هذه المقالة يتيمة إذ تصل إليها مقالات أخرى قليلة جدًا. فضلًا، ساعد بإضافة وصلة إليها في مقالات متعلقة بها. (مارس 2019) رود سميث معلومات شخصية الميلاد 15 نوفمبر 1949 (74 سنة) ساوثوست مواطنة الولايات المتحدة الحياة العملية المدرس�…

Coire Dubh in den Highlands Wer zweimal fällt, ist endlich tot (engl. Death On Site) ist ein Kriminalroman von Janet Neel, der 1989 bei Constable & Company Ltd.[1] in Großbritannien erschien. Inhaltsverzeichnis 1 Inhalt 2 Form 3 Deutsche Ausgaben 3.1 Verwendete Ausgabe 4 Einzelnachweise Inhalt Detective Chief Inspector John McLeish bei der Mordkommission von der Londoner Stadtpolizei New Scotland Yard macht Anfang August im schottischen Hochland mit seiner 29-jährigen Freundin Fra…

Line of tablet computers by Apple This article is about the line of devices. For the first device marketed with this name, see iPad Mini (1st generation). For the device currently marketed with this name, see iPad Mini (6th generation). Not to be confused with iPod Mini. iPad miniDeveloperApple Inc.ManufacturerFoxconn, Pegatron[1]Product familyiPadTypeTablet computerRelease dateNovember 2, 2012; 11 years ago (2012-11-02) (1st generation)Units sold600 millionOperating sy…

Estimates of killed and injured during the conflict in Ukraine, 2014–present Casualties in the Russo-Ukrainian War included six deaths during the 2014 annexation of Crimea by the Russian Federation, 14,200–14,400 military and civilian deaths during the war in Donbas (2014–2022), and up to 500,000 estimated casualties during the 2022 Russian invasion of Ukraine. Russian annexation of Crimea Main article: Annexation of Crimea by the Russian Federation During the Russian annexation of Crimea …

Bảo Ứng (chữ Hán phồn thể:寶應縣, chữ Hán giản thể: 宝应县) là một huyện thuộc địa cấp thị Dương Châu, tỉnh Giang Tô, Cộng hòa Nhân dân Trung Hoa. Quận này có diện tích 1483 ki-lô-mét vuông, dân số năm 2004 là 919.900 người. Về mặt hành chính, huyện Bảo Ứng được chia ra thành 15 trấn: An Nghi, Phạm Thủy, Hạ Tập, Liễu Bảo, Xạ Dương Hồ, Quảng Dương Hồ, Lỗ Đóa, Tiểu Quan Trang, Vọng…

نافذة حوار في برنامج حماية الملفات على نظام ويندوز إكس بي نظام حماية ملفات ويندوز[أ] (بالإنجليزية: Windows File Protection) (مُختصر: WFP) هي خدمة متكوِّنة في نظام تشغيل مايكروسوفت ويندوز تُراقِب باستمرار ملفات النظام المحمية في ويندوز 2000 وويندوز إكس بي أو ويندوز سيرفر 2003 وقد تقوم بع�…

Kiribati Athletics AssociationSportAthleticsAbbreviationKAAFounded1999 (1999)AffiliationIAAFAffiliation date1999 (1999)Regional affiliationOAAAffiliation dateSuspended since 2020HeadquartersSouth Tarawa, TarawaPresidentBrian FukuyamaOfficial websitewww.foxsportspulse.com/assoc_page.cgi?c=2-1153-0-0-0 The Kiribati Athletics Association (KAA) is the governing body for the sport of athletics in the Kiribati.[1][2] It is suspended by Kiribati National Olympic Committee and …